Food & Beverage

Optimization of food & beverage quality

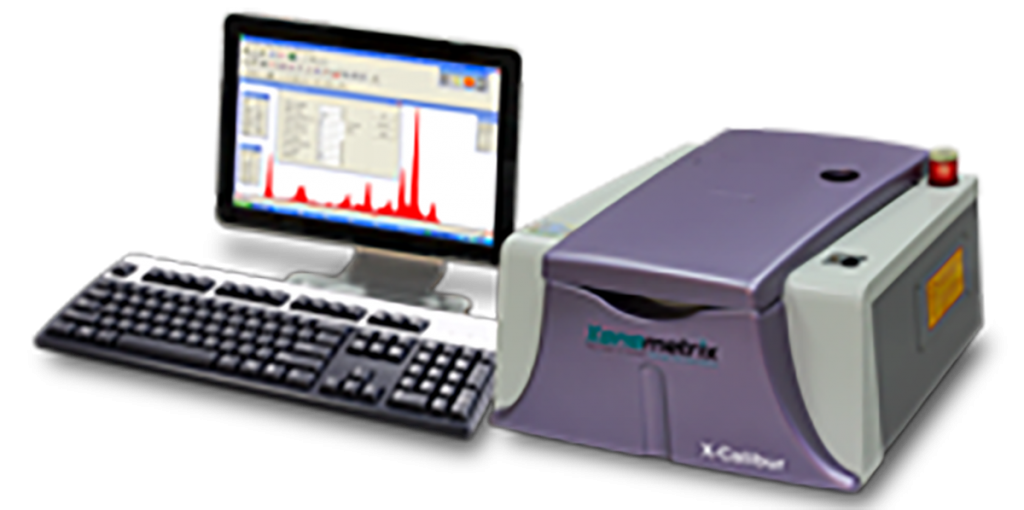

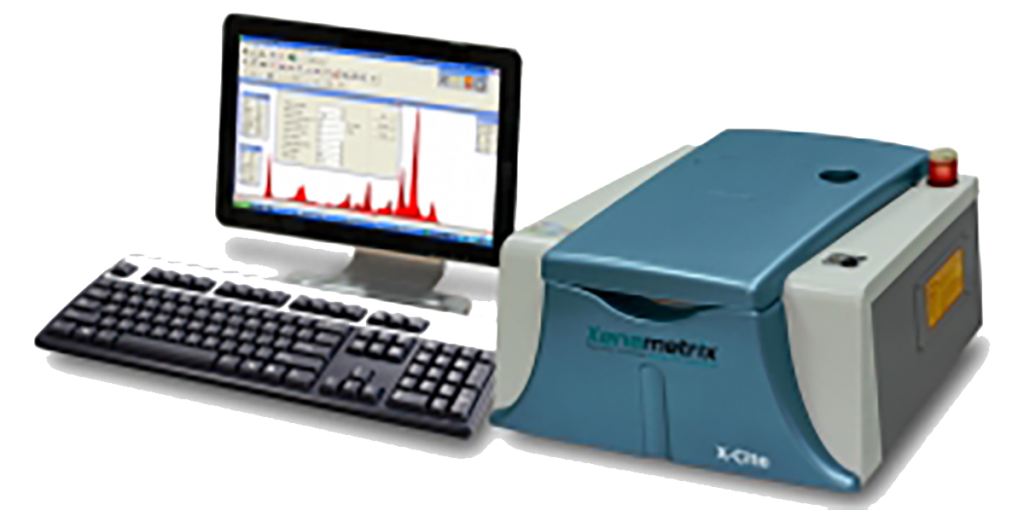

The Food & Beverage industry is a wide-scale and versatile industry, which is enforced by strict standards and regulations that makes it an ideal potential for the ED-XRF analytical systems. Using ED-XRF allows measuring a wide range of elements C (6)-Fm (100), at different concentration in almost all matrices – solids, powders and liquids.

One of ED-XRF technology’s advantages is that samples are analyzed in their native crude form without any sample preparation or sample destruction. Using traditional wet chemistry, such as ICP and atomic absorption, involves sample dissolution and element extraction into solvents. This procedure requires extensive sample treatment and causes measurement errors when sample dissolution or extraction into the solvent is not completed.

The ability to analyze samples in their native form provides an economic advantage with respect to chemicals and solvents, and the time required for analysis.

In addition, even non skilled personnel can conduct the analysis with a dedicated intuitive user interface.

This advanced technology is capable of providing qualitative and quantitative results with detection limits of 0.1-1 mg/kg, depending on the type of element being analyzed.

Various minerals and metals are being added during the food production process for extra nutritional value, that must be closely monitored to comply with food administration regulations such as the FDA and the European Medicines Agency (EMA). This analysis also identifies undesirable additives and contaminations that may be found in raw and processed food.

Not only can the ED-XRF method reduce manufacturing costs, but it can also improve food quality and help safeguard human health and even save lives. A large number of established applications already use the technology, some of which include:

- Chlorine in snack foods – Chlorine is monitored to control taste or assure compliance with low salt labeling of products. Snack foods such as potato chips, processed meat and cheese that are often high in salt level have been successfully analyzed by ED-XRF.

- Iron in flour, rice and other grain– Grains and processed flour have long been fortified with iron and ED-XRF instruments are used to monitor its levels.

- Calcium in orange juice, cheese, and other foods – Calcium has long been added to orange juice, and is frequently added to many other types of foods as a supplementary source of calcium for the prevention of osteoporosis.

- Titanium in cookies and snack cakes – Titanium dioxide is used to make cookies, cakes and fillings whiter and brighter. It exists in high concentration and is easily measured by ED-XRF.

- Iron in powdered milk – Iron is added to milk powder as a supplement, and is easily analyzed by ED-XRF.

- Na, Mg, P, Cl, K, Ca, Mn, Fe, and Zn in pet foods and animal feed – The nutritional value of pet foods and animal feed can be controlled by routinely monitoring the product with ED-XRF.

- Al and P in dough – Aluminum and phosphorus are other elements in addition to iron that can usually be found in dough and can be measured by ED-XRF.

- Ash in flour– The ash that remains when flour is burned is composed primarily of Na, Mg, K, and Ca oxides. The ash percentage and composition has an effect on taste and mouth feel of product made from flour, so they must be routinely analyzed. ED-XRF is an excellent method for performing this analysis.