Coating Thickness & Thin Films

Quality control of coating and thin film analysis

All industrial operations have processes in place to ensure efficiency and safety standards. Xenemetrix systems are perfectly suitable for complementing these processes.

Proper quality control of plated materials is important both for companies that are plating the components as well as for those companies that utilize the plated components in their manufactured goods. Product liability requires strict quality control in order to avoid defective coatings and eliminate problems such as rust, which can lead to production defects and/or product recalls.

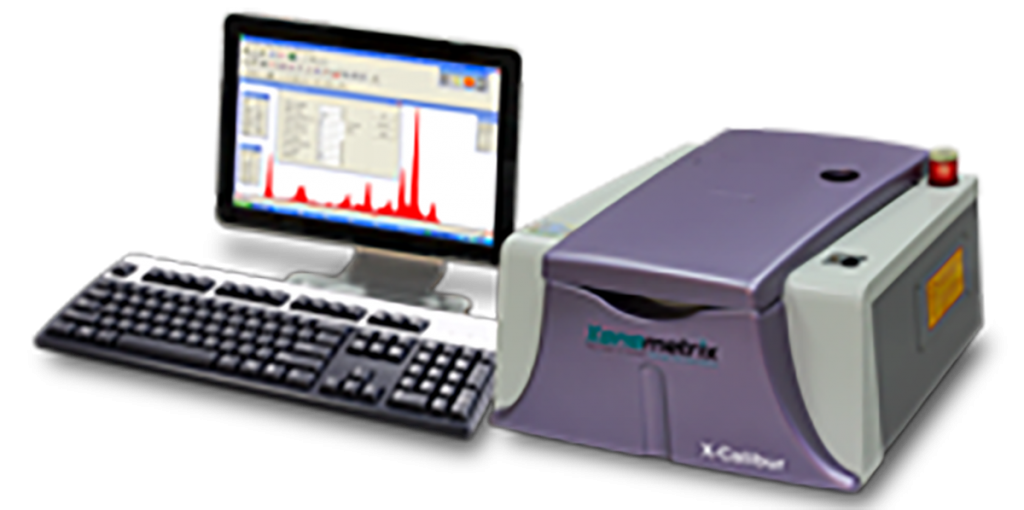

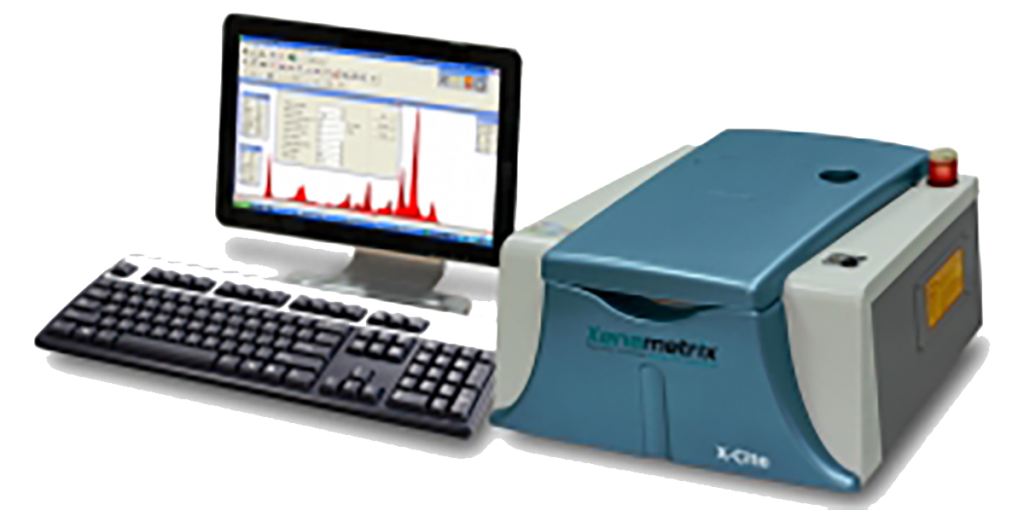

Large numbers of specially constructed XRF instruments are sold each year for monitoring plating thickness. Many of these coating thickness analyzers have a dedicated software that allows measuring the individual thickness of multiple layers and to determining the elemental content in different layers.

Xenemetrix Energy Dispersive X-ray Fluorescence (ED-XRF) spectrometers are the simplest, most accurate, non-destructive and economical analytical systems, using ED-XRF allows measuring a wide range of elements and concentrations with no need for sample preparations (heating or destroying the sample).

Our ED-XRF spectrometers can be calibrated to determine both coating thickness and coating quality for various types of materials. X-rays achieve superior penetration depths and can thus measure coatings in a manner which cannot be achieved by other technologies. If the coatings consist predominantly of one element, the analysis can very easily be made.

Optional Standard less fundamental parameters software provides thickness quantitative analysis with no standard materials requirement. The solution is applicable to various coating and thickness analysis fields.

A number of common coating applications include:

- Silicone on Paper, Tissue Paper, and Hygiene products– Silicone is used as a release coating on paper, so that adhesive labels do not stick. Silicone is used on tissue paper to make it feel softer. Silicone is also used in the liners of diapers and other hygiene products to repel moisture and to keep dry the side close to the skin. ED-XRF instruments have long been used for these applications.

- Platinum Catalyst in Silicone Resin– Platinum catalysts are used in silicone resins as a curing agent. It is added at concentration in the 100 ppm range and can be analyzed by ED-XRF.

- Phosphorus on Steel– Phosphate coatings are used to protect and pre-treat steels. Phosphorous can be measured along with iron and manganese which are occasionally also present in the coating.

- Sulfur and Phosphorus on Aluminum– Aluminum is coated or anodized by etching the surface with acid, which bonds to the aluminum making it much harder. The coating can be measured by ED-XRF by measuring the elemental sulfur or phosphorus on the surface.

- Copper on Silicon– These days, as many silicon wafer fabricators are switching to copper, monitoring them with XRF is made easier than ever. ED-XRF is usable for on-line process monitoring.

- Capacitors– Modern capacitors like tantalum capacitors are produced by coating a thin polymer with a thin layer of metal. The material is then rolled to form the capacitor. Aluminum is the most common metal, with tantalum representing an important niche. A variety of polymers are used including polyester, polypropylene and polycarbonate. ED-XRF instruments are ideal for monitoring the metal film thickness.

- Metalized Food Packaging– Many types of food are packed in foil pouches made from a polymer coated with metal. The oldest is aluminized Mylar, but titanium and zinc are also common, and other polymers can be used as well. While light transmission is used for many thin coatings, ED-XRF instruments are suitable for most applications, particularly those which require thicker coatings.

- Solar Power Cells– Most solar cells use a thin coating of metal alloy on a polymer substrate. These coatings are easily measured by ED-XRF.

- Conductive Coatings on Plastic– In order to comply with regulations on electrical noise, modern plastic cases for electronic equipment must be shielded. Shielding is often achieved by coating the plastic with a conductive layer which can be analyzed by ED-XRF.

- Vapor and e-Beam Deposition Coatings -Numerous elements are deposited in thin films by e-beam or vapor deposition methods. Virtually each and every element above atomic number 10 can be measured by ED-XRF.