Metal & Ore

Quality control of the various metal industry processes

Quality control of the various metal industry processes

Metal forms an essential material in modern manufacturing, metal products being used everywhere.

Using ED-XRF allows to measure a wide range of elements and concentrations – C(6)-Fm(100) – without the need for sample preparations (heating or destroying the sample). Samples can be measured in the form of loose powders or pressed into pellets and ready for measurement within seconds.

ED-XRF can measure larger sample volumes resulting in a better characterization of end products and provides high accuracy and precision with excellent detection limits (0.1 – 1 mg/kg).

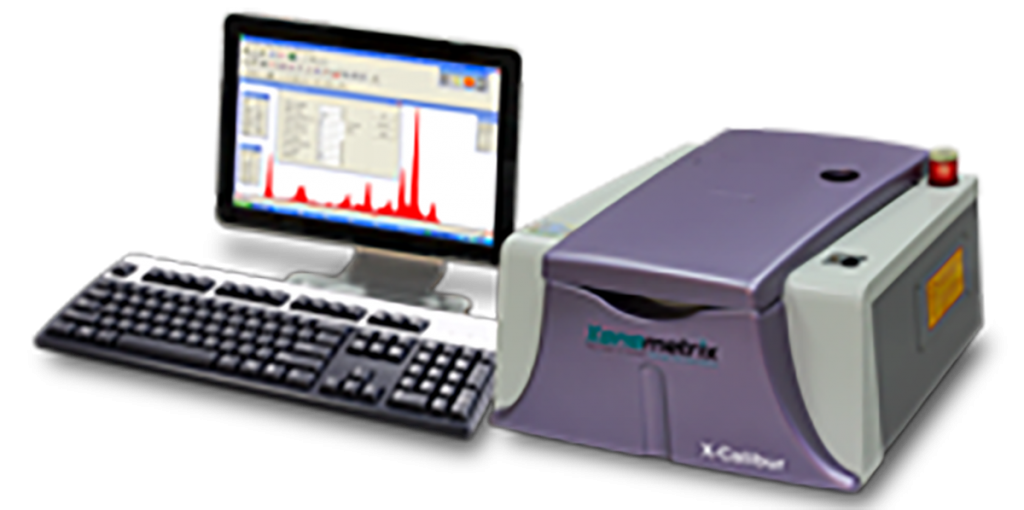

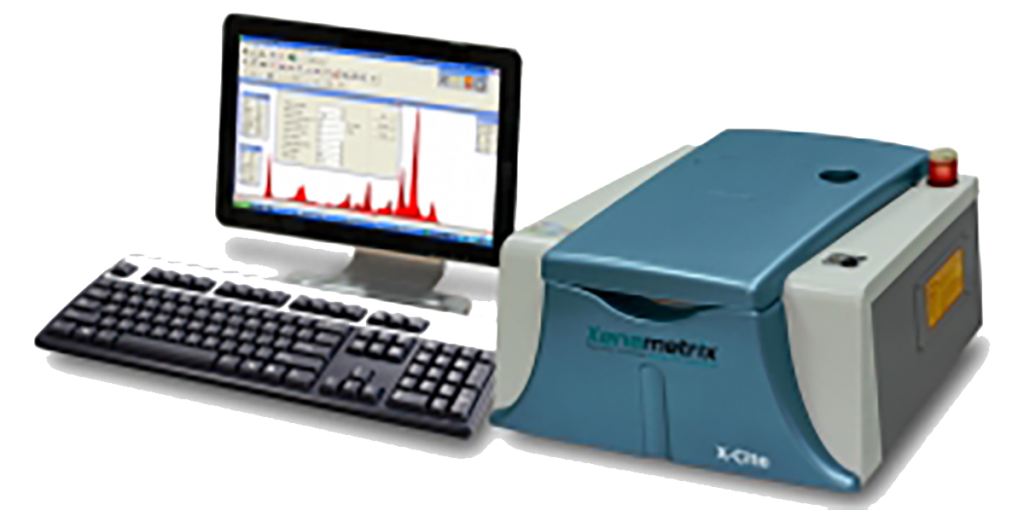

Energy Dispersive X-ray Fluorescence (ED-XRF) spectroscopy is one of the simplest, most accurate and economical analytical methods for the determination of chemical composition of various end or intermediate products in the metals industry. ED-XRF plays a dominant role in quality control of the various metal industry processes. Non-destructive elemental analysis can be performed in each step of the process, from ores to finished alloys.

ED-XRF is capable of easy and fast sorting between different steel grades, as well as forming a convenient tool for QA processing being an analytical on-line tool, providing immediate results.

- Alloy Analysis– Alloy analysis using Xenemetrix spectrometers has become a standard practice. Xenemetrix spectrometers identify most alloys and perform complete chemical analysis within a few seconds. High-level spectrometers perform quick and easy sorting and identification of all classes of alloys including: Iron, steel – low alloy and carbon steel, stainless steel, copper, brass, bronze, aluminum bronze, leaded brass and bronze, aluminum, nickel alloys, zinc alloys, cobalt alloys, titanium alloys , solders-tin, lead and silver.

- Precious Metals – Precious metals are always of interest for jewelry, industrial use, and investment purposes. With Xenemetrix X-PMA bench-top spectrometer, metals can be detected and tested for content and purity with very low operational costs and no need for sample preparations. The essential advantage of using Xenemetrix X-PMA analyzer is its high precision and accuracy. The X-PMA analyzer makes it possible to determine the elemental content of items offered for sale and their karat value within seconds.

- Ores, Slags, Feeds, Concentrates, and Tailings – ED-XRF plays an important role in each step of the metal production process. Large and small components are analyzed with ED-XRF instruments, and in many cases can even be measured on-line.

- Silicon Metal – Silicon forms an important metal in the semiconductor industry and high purity is required. ED-XRF is often used to monitor high silicon sands for impurities, and can be used throughout the refining process and during the wafer production. Specialized high performance ED-XRF equipment is specifically designed for wafer analysis.

- Metal Foil Thickness – Foils are produced from every conceivable elemental metal. The thickness of thin foils can be easily measured on-line by ED-XRF.