Key Applications:

Geological samples, cements, minerals, slag, ceramics, oxides, glass, metals, ferroalloys, sulphide, fluoride, alloys, etc.

Avoid the disadvantages derived from the use of gas:

- Temperature: ineffective control of the temperature

- Atmosphere: it is not the right atmosphere for the oxidation of samples.

- Pressure: gas pressure problems in high places.

- Safety: presence of flames with risk of intoxication or explosion.

- Safety: presence of flames with risk of intoxication or explosion.

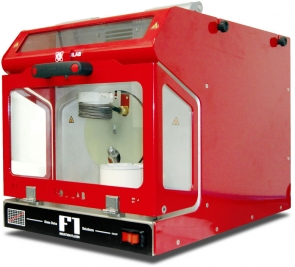

The new induction fluxers F1 and F2 have been specially created to speed up and facilitate the process of preparation of glass discs for their analysis via XRF, and solutions of AA for ICP. They can produce, accurately and fast, beads and solutions with classical flux (Borates) as well as undertaking high quality fusions of non oxidized elements with peroxide. It is effective both in high and in low temperatures. They can easily adapt to your production needs, as it is designed to accept up to ten fusion modules using the same control unit, becoming that way a real Production and Control System of discs and solutions. Also, both equipment admit crucibles of different materials, such as platinum, zirconium, nickel, etc., as the unit adjust automatically the best frequency of the resonant system for the type of crucible being used.

According to the trend to eliminate the combustible gases from laboratories, the F series represents a major technological progress in the fusion units, as it heats via electric induction homogeneously, quickly and efficiently. It is a highly automated unit with capacity to control and visualize in real time, and in an independent way, the fusion process of two samples simultaneously – in the F2 mode.

Despite the high temperatures it can reach in just a few seconds, the only parts heating up in the unit are the ceramic holders, thus allowing to reduce the periods between fusion cycles, as no cooling of heated up areas is needed.

Despite the high temperatures it can reach in just a few seconds, the only parts heating up in the unit are the ceramic holders, thus allowing to reduce the periods between fusion cycles, as no cooling of heated up areas is needed.

To its innovative induction heating system we must add a continuous temperature check up and a great software work. The result is a unit able to exhaustively control and modify at all times the fusion process of each of the samples, in real time.